Solder & Crimp Heat-Shrinkable Terminals

Application

Designed for high-reliability connections in harsh industrial environments. The series utilizes a Tin-Bismuth (Sn-Bi) low-temperature solder (138°C), enabling faster and more eco-friendly installation compared to traditional methods. Combining 33% thicker copper terminals with dual-wall heat shrink sealing, this solution effectively prevents corrosion, minimizes contact resistance, and enhances vibration resistance, delivering long-term stability for automotive, marine, and heavy-duty applications.

Series Overview

• Sealed Crimp & Solder Terminals: Dual mechanical and electrical reliability for high-vibra-tion environments.

• Heavy-Duty Sealed Solder Terminals: Enhanced conductivity and corrosion resistance with 33% thicker copper body

Features and benefits

• Lead-Free Alloy: Utilizes Sn-Bi low-temp solder (138°C) with high surface tension. It melts faster and offers controlled flow, ensuring a clean, eco-friendly bond.

• IP-Rated Sealing: Adhesive-lined tubing shrinks to create a robust waterproof seal, effectively preventing corrosion and voltage drops caused by oxidation.

• Vibration & Strain Resistant: The cured sleeve reinforces the joint, working with the crimp/solder bond to resist wire pull-out and fatigue under stress.

• Visual Quality Control: Transparent insulation and a 45° angled barrel facilitate verification of wire insertion and solder wetting, ensuring a reliable connection.

Notes:

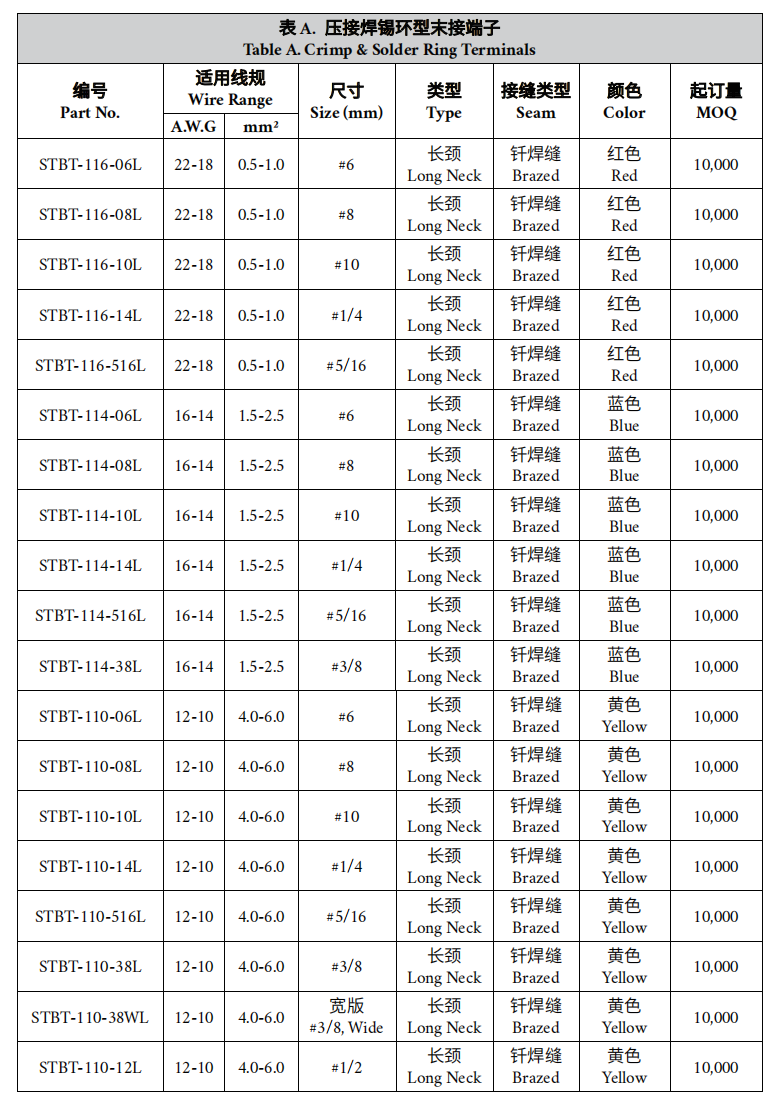

• See tables for detailed dimensions, wire compatibility, and part numbers.

• Custom sizes and color coding available upon request.

• Specifications subject to change; MOQ may vary from standard packs.

Specifications